How to Design for CNC Milling

In this paper, MGX200 CNC Lathe bed selected for the complete static and vibration analysis. The examination work completed to lessen the heaviness of bed without break its basic inflexibility and the precision of the machine instrument by expelling material.In this work, 3D CAD model done by using Autodesk Inventor Professional 2018 Software and analysis carried out in ANSYS 16.2 Software.

CNC Machine Buyer’s Guide Types, Uses, Price, & Definitions

Computer numerical control (CNC) milling machines have been a great asset to manu-facturing industries, since they increase manufacturing range and flexibility [1], while sustaining high milling speed and precision [2]. The advent of CNC milling machinery therefore brings reduced manufacturing times and increased quality.

DIY CNC Milling Machine Build (Part 1) CNC Mill CAD design and the Y axis Tazacnc

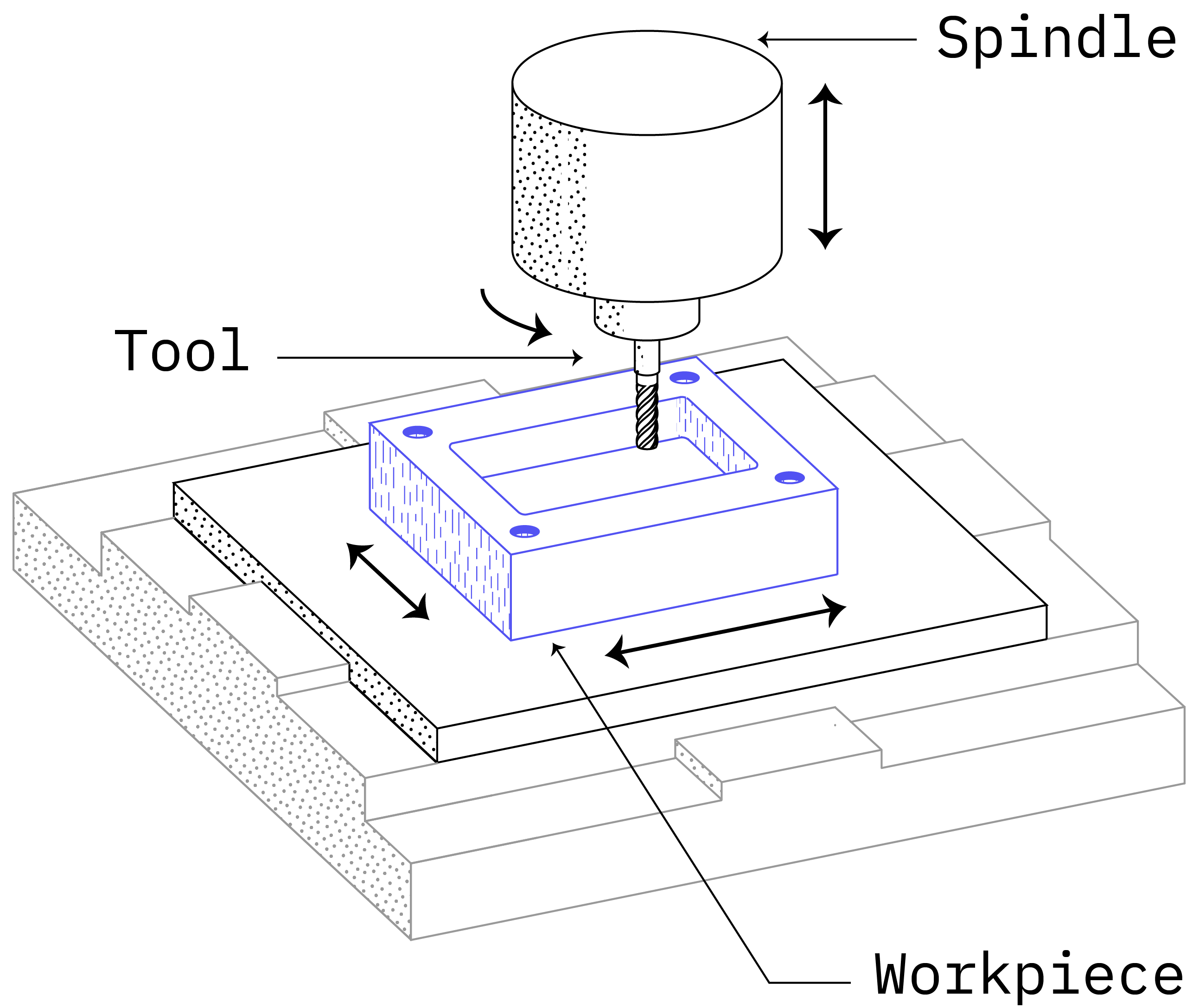

CNC milling, what is it? CNC is an acronym for 'Computer Numerically Controlled'. In manufacturing what is controlled is tool movement, whether it is an extrusion nozzle in 3D printing or a spinning cutter in CNC milling. Milling refers to a reductive process of removing material with a rotating cutter which has knife edges to slice off chips.

CNC Machine Definitive Guide 11 different CNC Machine Type

The design of the CNC milling machine CC BY Authors: Piotr Boral Czestochowa University of Technology Abstract and Figures CNC machine tools are currently predominating in the.

The Essential Guide To CNC Milling Machines Hwacheon Asia Pacific Pte. Ltd.

To design the mill, is is necessary to establish some idea about the typical loads experienced by a machine during a milling operation. This will allow one to determine what Figure 1. Roland MDX-15 is a desktop CNC milling machine produced by Roland DGA. While it does meet most of the requirements for the device

4 Axis CNC Milling Detail Precision

CNC Machining is a very broad subject and there are many ways to do most things. Covering all options would fill volumes and isbeyond the scope of any one book or course. The goal of this course is not to turn and engineer into a journeyman machinist. Rather, it is to show how to use CNC to make common types of

4 Axis CNC Machining The Definitive Guide

The presented virtual modeling methods and milling machine tool simulations make it possible to design, perform complex analyses, test, optimize, and use various types of control structures in the computer simulation. The development and revision of milling machines and components are continuous. With the help of computer technology, we can simulate some activities in a manufacturing system.

(PDF) Project and construction of a small CNC milling machine

It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. The development of NC machine tools started from a task supported by the US Air Force in the early 1950's, involving MIT and several machine-tool manufacturing companies.

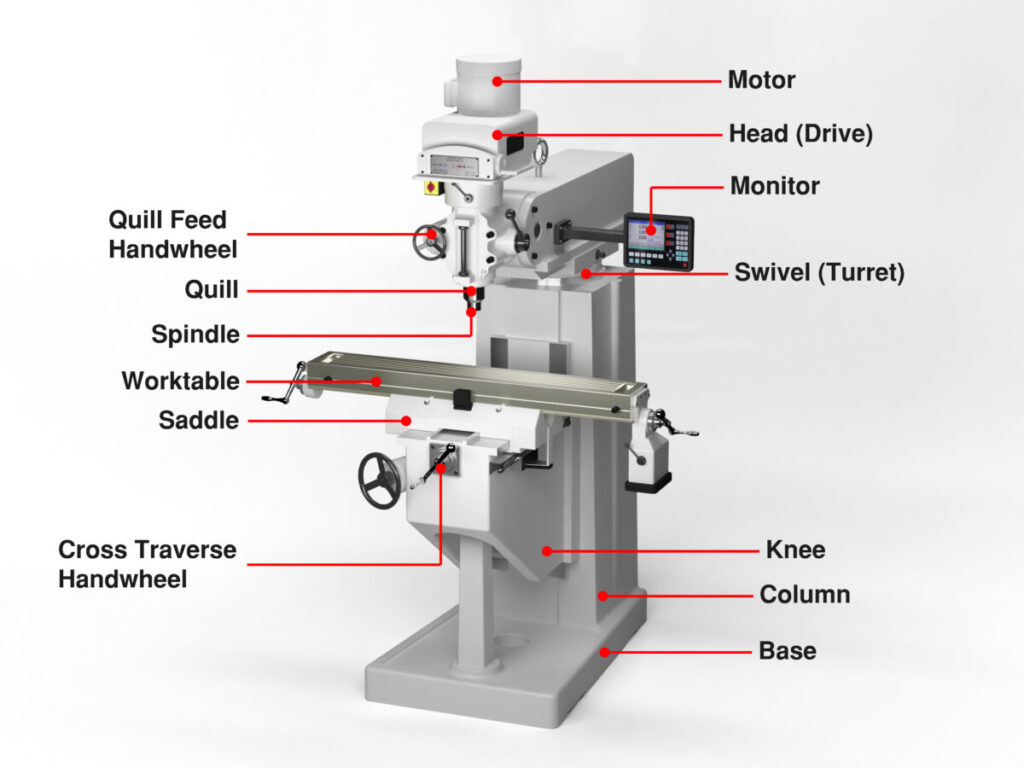

What Are The Main Components Of A CNC Milling Machine?

This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing requirements. The following is a.

How to design parts for CNC machining 3D Hubs

CNC (Computer Numerical Controlled) Machining is a means to remove material using high speed, precision machines that use a wide variety of cutting tools to create the final design. CAM (computer

CNC Machining 101 Milling and Turning Merchants Fabrication, Inc

Shown below is the authors' design of a 4-axis welded-construction CNC milling machine with enhanced rigidity and machining accuracy, which is intended to be, at the same time, a test stand [4]. The worm described in the article was made on this milling machine [5].

CNC Mills Chester Machine Tools

Get started with a DFM expert. Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy eficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like Fast.

Bryan Cera My DIY CNC

3 DESIGN OF CNC MILLING MACHINE Design of the milling machine will correspond to its intended use. This machine tool will be used for machining easily machinable materials such as artificial wood, plastic and aluminium alloys. The design will be based on the minimum work area dimensions, which are 200 x 200 x 150 mm. Additionally,.

CNC Machining Walt3D LLC

2 Feed Drive Modelling of a CNC Milling Machine 3 2.1 Introduction 3 2.2 Physical Architectur CNC Millineg o Machinf thee 4 2.3 Modelling of Fee Systed Drivm 6 e Control 2.3.1 Velocity Loop Modelling of the Feed Drive 6 2.3.2 Positio Loop Modellinng of the Feed Drive 10 2.3.3 Stat Space Modelline g of the Feed Driv Positioe n Contro Systel m 13

CNC Milling a Complete Guide to Understand the Process (2022)

The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.

CNC Milling for Makers Basics Techniques Applications PDF Free Download Free eBooks, PDF

The presented virtual modeling methods and milling machine tool simulations make it possible to design, perform complex analyses, test, optimize, and use various types of control structures..